RCB-1S Stainless steel corrosion proof bearing | ||

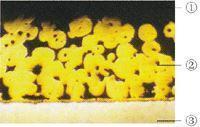

MATERIAL STRUCTURE | ||

|  | 1. PTFE/Pb composition, 0.01-0.03mm, anti-abrasion material, which will form a lubricating film during operation. 2. Bronze powder layer, 0.2-0.35mm, which further strengthen the combination of the bronze plate and PTFE layer and transfer the heat more quickly. 3. Bronze plate, bear high load and transfer heat, anti-corrosion. |

TECHNICAL DATA

Advantages of dry bearing

(1) Applicable occasions

For places where oil cannot be added or it is difficult to add oil, it is not suitable to use oil lubrication or use less oil lubrication. It can be used without maintenance or less maintenance, and also avoid the risk caused by insufficient oil supply.

(2) No oil supply is required

It does not need oil supply device, so it can save a lot of installation and operation costs. Oil free can greatly simplify design and structure, reduce cost and save design time.

(3) Green environmental protection

There is no need to recycle waste oil, which is conducive to environmental protection.

APPLICATION CHARACTER

1. PTFE with oil fibre can protect the shaft, while machine in operation. |

|